Yaskawa-Servoantrieb-Debugging-Verfahrensschritte

Release-Zeit:2023-09-14 14:57:39

1. Basic wiring

The main power input is 220V, which is connected from L1 and L3 (the actual use should refer to the operation manual); Control power input r, t can also be directly connected - 220V; Motor wiring see page 22, 23 of the operation manual, encoder wiring see the operation manual, do not connect wrong.

Second, test steps

1.JOG test machine function Yaskawa servo can be tested only according to basic wiring; When the digital display is in the initial state 'r 0', press the 'SET' key, then press the 'MODE' key continuously until the digital display is' AF -- AcL ', then press the up and down keys to 'AF-JOG'; Press the 'SET' key to display 'JoG -' : press and hold the '^' key until 'rEAdy' is displayed; Hold down the '<' key until 'SrV-on' is displayed; Press and hold the '^' key to rotate the motor counterclockwise, press the 'V' motor to rotate clockwise, and its speed can be set by the parameter Pr57. Press 'SET' to end.

2. Yaskawa servo internal speed control mode COM+ (7-pin) is connected to +12 -- 24VDC,COM- (41-pin) is connected to the DC source; SRV -- ON (pin 29) connected with COM-; Parameter No.53 and No.05 should be set to 1: (Note that such parameters should be written into EEPROM after modification and re-powered) Adjust parameter No.53 to make the motor rotate. The parameter values are the rotational speed, with positive values for counter-clockwise rotation and negative values for clockwise rotation.

3. Yaskawa servo position control mode

COM+ (7-pin) is connected to +12 -- 24VDC, and COM- (41-pin) is connected to the DC power source; SRV -- ON (pin 29) is connected to COM-LUS1 (pin 3), SIGN1 (pin 5) is connected to the positive terminal of the pulse source (+5V); PLUS2 (pin 4) is connected to pulse signal, SIGN (pin 6) is connected to direction signal; Parameter No.02 is set to 0, No42 to 3, and No43 to 1. PLUS (4 pins) into the pulse signal, can make the motor rotation; Change SIGN2 to change the motor steering. In addition, adjusting parameters No.46 and No.4B can change the number of pulses required per revolution of the motor (that is, electronic gear).

-

202306-09

202306-09ABB-Roboterprogramm Laufgeschwindigkeit langsame Reparaturschritte

1, prüfen Sie, ob das Programm logische Anweisungen enthält (oder andere Anweisungen, deren Ausführung keine Zeit in Anspruch nimmt), da solche Programme Ausführungsschleifen verursachen, wenn die···

-

202309-07

202309-07YOULI Multiway valve - Multiway valve regulation method

1. Unter normalen Bedingungen sollte der Öffnungsdruck des hydraulischen Mehrwegeventils, bevor es das Werk verlässt, nacheinander auf den vom Benutzer gewünschten Einstellwert eingestellt werden. ···

-

202308-10

202308-10Maintenance steps of Eston Palletizing robot

Erstens: MaschinenreinigungFirst, disconnect the power supply and remove debris around the machine. Wipe the surface of the machine with a clean cloth to ensure that there is no dust, grease and other···

-

202212-29

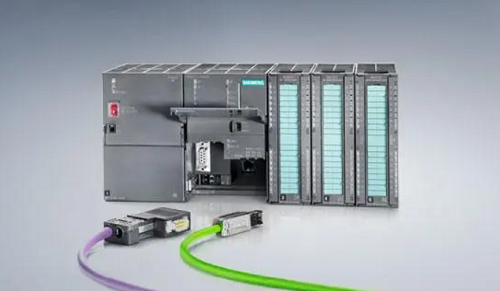

202212-29Hinweise zum Einsatz von Siemens Frequenzumrichtern

1. Die Ausgangsleitungsseite des Siemens-Frequenzumrichters kann nicht kurzgeschlossen werden, um den Kondensator zu kompensieren, noch kann der Kondensator kurzgeschlossen werden, um die hohen Obersc···

-

202301-28

202301-28Siemens PLC steuert Yamaha-Roboter

In diesem Beitrag wird die Steuerungsstrategie des von Siemens PLC gesteuerten Yamaha-Roboters vorgestellt, bei der der externe IO-Port zur Einstellung des Befehlsworts verwendet wird, so dass die SPS···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Gebäude 26, Gemeinde Liyuan, Bezirk Chaoyang, Peking, China

Gebäude 26, Gemeinde Liyuan, Bezirk Chaoyang, Peking, China